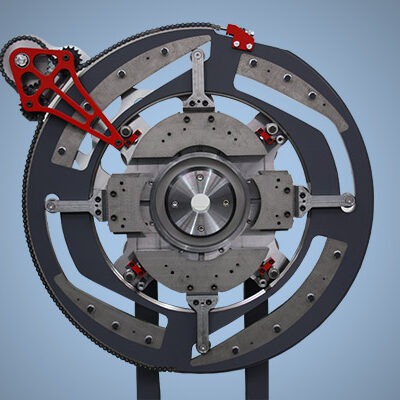

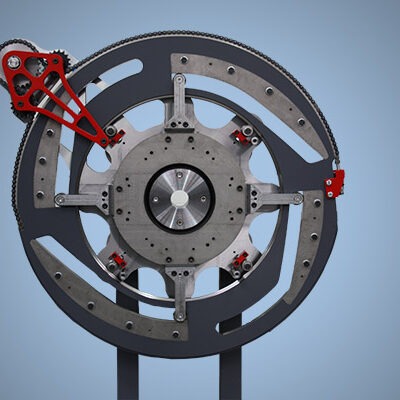

Plastics and their extrusion are a highly specialised field in mechanical engineering. Here, many requirements overlap, and a company that really wants to present something new needs the courage to take an untrodden path. This is exactly what iNOEX does: presenting sound and creative solutions to its customers.

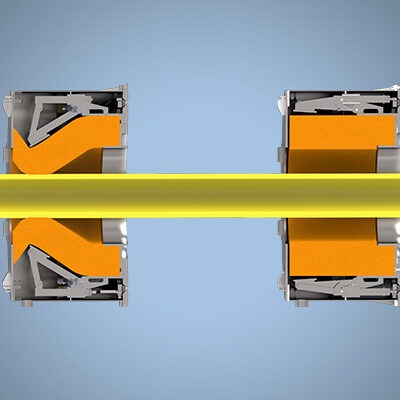

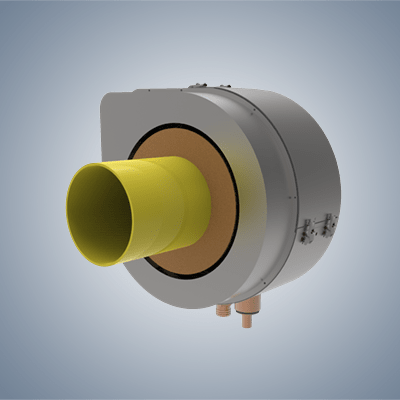

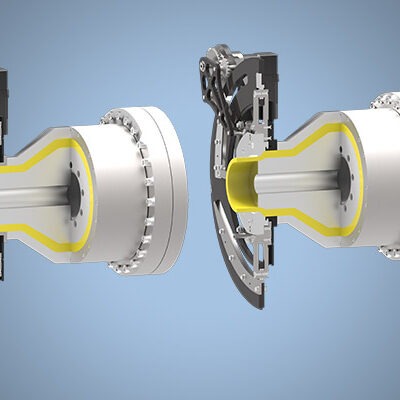

iNOEX’ vision is to modify the tube dimension at a plastic extrusion line during the ongoing process. This idea presents an enormous challenge to designers and process engineers. Our know-how helped us to develop a variable vacuum tank sealing and a tool head modifying the cross section after the extrusion nozzle; together with the process engineers we combined concept and construction and implemented the project.